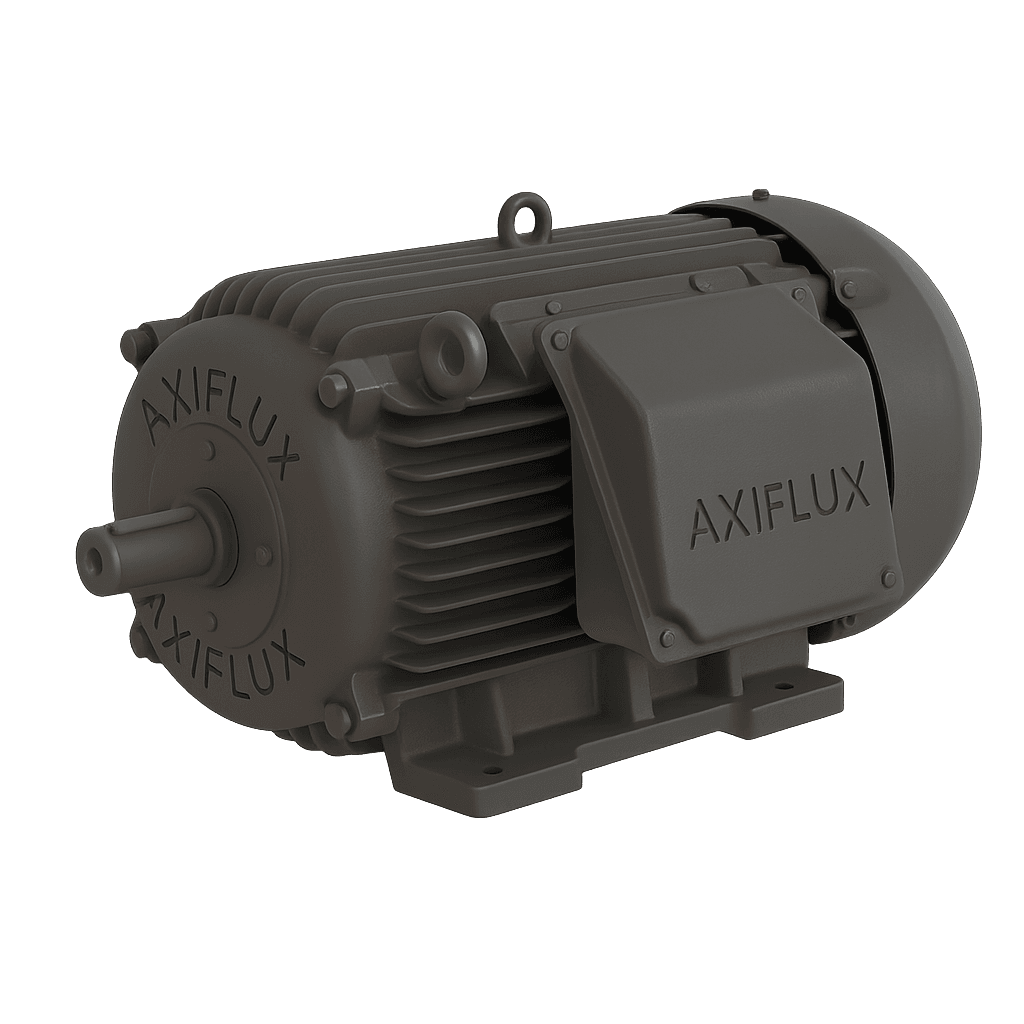

AMFA Electric Motor

The world's first modular, real-time, software-reconfigurable electric motor and generator, delivering unparalleled efficiency and power density unlocking new market opportunities.

The Only Design that FundamentallyChanges the Architecture of the Electric Motor

AMFA is the only motor technology that redefines efficiency and control, addressing global energy challenges. With electric motors consuming over 50% of global electricity, AMFA offers a breakthrough solution for cutting carbon emissions; the first major redesign in over 100 years.

Unprecedented Efficiency

Electric motors consume 53% of global electricity, with most running at full power regardless of need.AMFA's precision control matches output to actual demand, delivering measurable results: 50%+ savings in HVAC, 20-50% in mining, and 30-60% in industrial applications—all while maintaining optimal performance.

Revolutionary Architecture

AMFA integrates inverter and motor into a single package with embedded modular electronics.This unique design enables direct AC power conversion without DC intermediaries, reduces complexity, and provides built-in redundancy. If one module fails, others compensate—ensuring continued operation with exceptional torque density in a compact footprint.

"AMFA's breakthrough isn't just an improvemen; it's a complete rethinking of motor design principles that breaks through conventional limitations."

Revolutionary Architecture,Unmatched Performance

AMFA represents a fundamental shift in motor design that conventional solutions simply cannot match

Traditional variable speed solutions are fundamentally limited by their separate motor and drive design, which creates inherent challenges that:

Our proprietary Adaptive Magnetic Flux Array represents a fundamental redesign of electric motor architecture that:

AMFA achieves what conventional motor designs physically cannot

Transforming Industries with AMFA

AMFA's energy efficiency and advanced features deliver tangible benefits across diverse sectors.

Future of Efficient HVAC

Heating, Ventilation, and Air Conditioning (HVAC): AMFA achieves energy reductions of more than 50% compared to conventional fixed-speed motors. It dynamically optimizes airflow to match real-time demand instead of switching continuously.

Impact: Slashes building operational costs and significantly cutting carbon emissions.

Future of Efficient Mining

Mining Operations: AMFA drives 20-50% energy savings in ventilation through Ventilation on Demand (VoD) and delivers substantial efficiencies in energy-intensive crushing and grinding circuits. This is currently not possible due to physical constraints within mines.

Impact: Improves the economic viability of processing lower-grade ores and fosters safer, greener mining practices.

Future of Sustainable Industry

Industrial Processes (Pumps, Fans, Compressors): AMFA's inherent variable speed operation and direct-drive capabilities yield energy savings that can exceed 30-60% over fixed-speed motors, optimizing systems far beyond traditional VSDs.

Impact: Boosts overall industrial efficiency, lowers production costs, and enhances sustainability. Actively drives global decarbonization efforts and supports critical sustainability initiatives.

Future of Energy Generation

Redundancy reduces turbine downtime. A module fault allows continued operation minimizing reliance on heavy cranes cutting maintenance costs. High torque density facilitates compact, gearbox-less generator designs, eliminating a major failure point and improving efficiency.

Impact: Significantly lowers the Levelized Cost of Energy (LCOE) and accelerates the deployment of wind power.

Future of Public Transport

Superior Size, Weight, and Power (SWaP) profile maximizes payload or battery capacity. High operational efficiency improves vehicle range. Inherent redundancy provides vital "limp-home" capability and enhances the dependability of safety-critical systems.

Impact: Accelerates the adoption of electric powertrains in commercial trucks, buses, and off-highway equipment, making them more practical and safer.

Future of Marine Propulsion

High torque density is ideal for direct-drive propellers or podded thrusters, eliminating gearboxes, improving hydrodynamic efficiency, and reducing underwater noise. Inherent redundancy is invaluable for vessel safety, especially for single-propulsion systems or critical maneuvering thrusters. The integrated, sealed design offers superior resistance to harsh marine environments.

Impact: Delivers fuel savings, extends range in electric/hybrid systems, enhances vessel maneuverability, and ensures operational reliability at sea.

Core Technology Patented Innovation

AMFA's patented architecture represents a fundamental redesign of both motor and control electronics

AMFA Technology Architecture

Modular, integrated motor and electronics with direct AC power processing

Modular ElectronicsPatented

Intelligent modules embedded within the motor provide redundancy and distribute workload for optimal performance and reliability.

Technical Specifications

- Module Redundancy: N+2

- Distributed computing

- Real-time adaptation

Modular Motor ConstructionPatented

Inherently modular core architecture with coils and yokeless axial flux magnet arrays synergizes with electronic modules.

Technical Specifications

- Yokeless design

- Adaptive flux arrays

- High magnetic efficiency

Direct AC FunctionalityPatented

Operates directly from AC power, with modules performing efficient AC-to-AC conversion without intermediate DC bus.

Technical Specifications

- No DC intermediary

- Reduced conversion losses

- Higher system efficiency

Integrated Design (IP66)Patented

Power electronics and control logic are integrated within the motor housing, dramatically reducing size, weight, and power requirements.

Technical Specifications

- IP66 environmental protection

- Reduced footprint

- Simplified installation

Scalability & RedundancyPatented

Standardized modules enable easy scaling from kilowatts to megawatts while providing fault tolerance that allows continued operation even if a module fails.

Technical Specifications

- kW to MW applications

- Built-in redundancy

- Hot-swappable components

High Torque DensityPatented

Exceptional torque output enables smaller motors and direct load connection, eliminating the need for gearboxes in many applications.

Technical Specifications

- 2-3x conventional torque density

- Direct drive capability

- Gearbox elimination

Patent-Protected Technology

AMFA's technology architecture and control methods are protected by multiple granted patents

Technology ComparisonHow AMFA Measures Up

A comprehensive analysis of how AMFA technology outperforms conventional motor solutions across critical performance metrics

| Feature / Metric | Fixed Speed Induction/PSC | Standard ECM (HVAC) | Induction Motor + VFD | High-Eff. Sync. + VFD | Axiflux AMFA |

|---|---|---|---|---|---|

| Potential Peak Efficiency | Medium | High | Medium | High | Very High |

| Partial Load Efficiency | Very Low | High | High | High | Very High |

| Control Precision | None | Variable Speed | High | Very High | Very High |

| Torque Density | Low | Medium | Low | Medium | Very High |

| Inherent Redundancy | None | None | None | None | High |

| Reliability | Medium | Medium | Medium | Medium | High |

| Maintenance Needs | Low | Low | Medium | Medium | Low |

| System Install Complexity | Low | Medium | High | High | Low |

| SWaP | High | Medium | High | Medium | Very Low |

| Initial Cost | Low | Medium | Medium | High | Competitive |

| TCO | High | Medium | Medium | Medium | Low |

Efficiency & Performance

Reliability & Maintenance

Implementation & Cost

Performance Scale

Key Takeaway

AMFA technology excels across critical performance metrics, offering a unique combination of superior efficiency, control, reliability, and compactness, leading to a compelling Total Cost of Ownership despite competitive initial pricing.

Partner With UsFor Custom Solutions

Axiflux works directly with industry leaders to develop tailored AMFA solutions for specific applications and unique challenges.

- Custom motor designs for your specific requirements

- Co-development partnerships for breakthrough products

- Industry-specific optimizations for maximum impact

- Integration support for existing systems and products

Collaboration Areas

OEM Integration

Incorporate AMFA technology into your product lineup with our engineering support

Research Partnerships

Collaborate on pushing the boundaries of electric motor technology

Customized Solutions

Develop specialized AMFA motors for your unique industry challenges